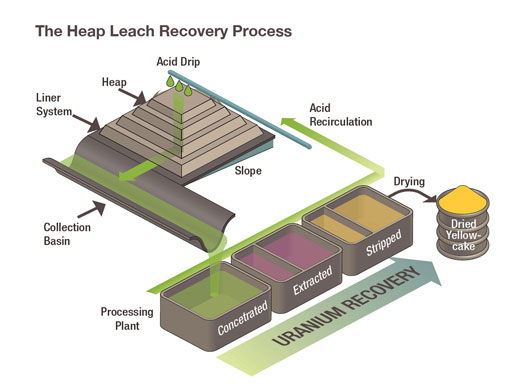

Heap Leach and Ion-Exchange Facilities

Through the years, the U.S. Nuclear Regulatory Commission (NRC) has licensed numerous uranium recovery facilities in the United States, which used a variety of extraction methods. In addition to conventional uranium milling and in situ recovery (ISR), which are currently used to extract uranium from ore, some NRC-licensed facilities used extraction methods known as heap leaching or ion-exchange. Such facilities no longer operate and are in the process of decommissioning. Nonetheless, heap leaching has also been used to extract uranium from ore at conventional mills, and ion-exchange procedures have been used to separate uranium from the liquid extract at both conventional mills and ISR facilities.

Heap leach/ion-exchange operations involve the following process:

-

Small pieces of uncrushed ore are placed in a "heap" on an impervious pad of plastic, clay, or asphalt, with perforated pipes under the heap.

-

An acidic solution is then sprayed over the ore to dissolve the uranium it contains.

-

The uranium-rich solution drains into the perforated pipes, where it is collected and transferred to an ion-exchange system.

-

The ion-exchange system extracts and concentrates the uranium to produce a material, which is called "yellowcake" because of its yellowish color.

-

Finally, the yellowcake is packed in 55-gallon drums to be transported to a uranium conversion facility, where it is processed through the stages of the nuclear fuel cycle to produce fuel for use in nuclear power reactors.