Deconversion of Depleted Uranium

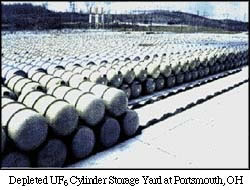

Natural uranium extracted from the ground consists on average of uranium-238 (U238) at 99.3% concentration and uranium-235 (U235) at 0.7% concentration. The uranium-235 component must be enriched to between 3-5% for use in nuclear power reactor fuel in the United States. During enrichment, large quantities of natural uranium (with 0.7% U235) are processed to increase the concentration of U235. The end product is enriched uranium with U235 at 3-5% concentration. The uranium with a higher concentration of U235 (enriched uranium) is used for fabricating fuel for nuclear reactors. During the enrichment process, large quantities of depleted uranium (uranium with 0.2-0.3% U235) or "tails," are produced. These tails exit the enrichment process as waste in the chemical form of uranium hexafluoride (DUF6). These tails are transferred into 14-ton cylinders which are maintained during temporary storage in large yards near the enrichment facilities.

A process called "deconversion" chemically extracts the fluoride from the DUF6 and produces chemically stable compounds of uranium, commonly referred to as uranium oxides. The chemically stable compounds of uranium are more suitable for disposal as low-level radioactive waste. For additional information, see the following topics on this page:

This page includes links to files in non-HTML format. See Plugins, Viewers, and Other Tools for more information.

Purpose of Deconversion

Enriching 1,000 kilograms (kg) of natural uranium to 5% U235 produces approximately 85 kg of enriched uranium hexafluoride (UF6) and about 915 kg of UF6 depleted to 0.3% U235. As a result, the enrichment process produce tons of depleted UF6 tails per year in the United States. These tails are then transferred to storage cylinders. The uranium in these cylinders are depleted in the isotope U235, i.e., consists of the uranium isotope, U238, in high purity (99.7%) with only small concentrations of other uranium isotopes (e.g., U235 0.3% and U234 < 0.002%) present. In addition, the cylinders contain small quantities of daughter products which results from the natural radioactive decay of the uranium. U238 has a low specific activity and a high density. Due to the high density, it is effective at self-shielding. The high purity of U238 in storage cylinders (full cylinders with solid DUF6) limit the radiological hazard (i.e. direct radiation coming from the full cylinders). Solid UF6 reacts slowly with moisture in the air to produce uranyl fluoride and hydrogen fluoride gas. In sufficient concentrations, these compounds have the potential to produce hazardous chemical or radiological exposures.

The deconversion process significantly reduces the chemical hazards associated with depleted uranium. The deconversion process separates the fluoride atoms from the UF6 and replaces them with oxygen. The chemical compounds that result are depleted uranium dioxide (UO2) and depleted tri-uranium oct-oxide (U3O8). These oxides are similar to the chemical form of uranium in nature. The compounds are chemically stable, compared to depleted UF6, and are generally suitable for disposal as low-level radioactive waste at a licensed disposal facility.

Depleted uranium has a lower specific radioactivity per mass than natural uranium because the enrichment process reduces the percentage of other isotopes, e.g. U235 and U234. However, the specific radioactivity of the depleted uranium storage containers increases over time as the daughter products, removed during the uranium recovery and conversion processes, return to natural levels due to radioactive decay. Most of the daughter products return to equilibrium levels over the course of several million years.

Another purpose of the deconversion process is to recover high purity fluoride compounds which have commercial value. Fluoride compounds are used in the production of refrigerants, herbicides, pharmaceuticals, high-octane gasoline, aluminum, plastics, electrical components, and fluorescent light bulbs.

Hazards at Deconversion Facilities

Chemical exposure is the dominant hazard at deconversion facilities because uranium and fluoride compounds (such as hydrogen fluoride) are hazardous at low levels of exposure.

- If DUF6 comes in contact with moisture in the air, a chemical reaction forms hydrogen fluoride and uranyl fluoride. Hydrogen fluoride is a corrosive acid that can cause severe burns upon contact and inhalation.

- Liquid hydrogen fluoride is hazardous if a dermal (skin) or ocular (eye) exposure occurs.

- Depleted uranium is a heavy metal. If ingested, it results in internal radiological exposure and can cause damage to the kidneys.

Deconversion facilities are designed to reduce the likelihood and consequences of accidental releases of hazardous radiological and chemical compounds through safety systems, onsite and offsite monitoring, and emergency planning.

Deconversion Facilities in the United States

Regulated by the NRC

On October 2, 2012, the NRC issued a 40 year

license for International Isotopes Fluorine Products, Inc. (IIFP), a subsidiary of International Isotopes, Inc., to construct and operate a fluorine extraction and depleted uranium deconversion facility near Hobbs, NM. If constructed, the

Fluorine Extraction Process and Depleted Uranium Deconversion (FEP/DUP) Plant will be the first major commercial deconversion facility licensed by the NRC to convert depleted UF

6 to a uranium oxide for the purpose of recovering fluorine.

Regulated by Agreement States

The United States has one operating facility that converts uranium fluoride to uranium metal, which is regulated by the State of Tennessee under an Agreement State license in accordance with Title 10, Part 40, of the Code of Federal Regulations (10 CFR Part 40), "Domestic Licensing of Source Material." At this facility in Jonesborough, Tennessee, Aerojet Ordnance Tennessee, Inc., fabricates uranium metal for the U.S. Army to use for defense purposes. This plant converts depleted UF4 into metal using a process that does not produce significant quantities of fluorine or hydrogen fluoride as reaction products.

Regulated by U.S. Department of Energy

The U.S. Department of Energy (DOE) constructed two depleted uranium deconversion facilities next to the gaseous diffusion plants near Paducah, KY (1950-2013) and Portsmouth, OH (1950-2000) that were used for uranium enrichment prior to being closed. The deconversion plants began operation in 2010 and 2011, respectively.1 Together, these plants will deconvert tons of depleted UF6 in storage in the DOE inventory. The inventory of depleted uranium is projected to require 15-30 years to deconvert. See Depleted UF6 Management for additional detail regarding the DOE program.

Regulated Over Seas

The URENCO USA enrichment facility in Eunice, New Mexico is a commercial enrichment facility licensed in 2010. The facility is generating depleted uranium hexafluoride and is authorized (as of 2016) to possess up to 251,000,000 kgs of depleted uranium hexafluoride. URENCO has plans to develop a Tails Management Facility (TMF) for deconversion in the United Kingdom.

For additional information, see our Frequently Asked Questions about Depleted Uranium Deconversion Facilities.